Insure Pulse

Combines Xemium with Plant Health Benefits1 to maximize pulse production

- The first fungicide seed treatment with Xemium, for unique translocation and mobility characteristics

- Delivers more consistent and continuous protection against key seed and seedling diseases, including ascochyta

- Plant Health Benefits ensure greater germination for improved emergence and enhanced seeding vigour, including better management of minor stress2

1 Plant Health Benefits refer to products that contain the active ingredient pyraclostrobin.

2 All comparisons are to untreated, unless otherwise stated.

Labels & SDS

11 AVAILABLE

Applicable On

Field Peas

Lentils

Soybeans

Labels & SDS

Additional Resources

Benefits of Insure Pulse

- Insure Pulse has three active ingredients from Groups 4, 7 and 11 for multiple modes of action and premium, broad-spectrum control of key diseases affecting pulse and flax crops.

- In addition, Insure Pulse offers greater germination for improved emergence and enhanced seedling vigour with Plant Health Benefits1, plus the translocation and mobility characteristics of Xemium for more consistent and continuous protection.

- Xemium has unique mobility characteristics, enabling it to spread from roots to shoots and throughout the seedling. This plant-wide distribution, protects the crop right from initial development, providing reliable, consistent disease control. Control of key diseases causing root rot, seed rot and, seedling blight contributes to a better plant stand, the foundation for a healthier, more profitable crop.

Performance Trials

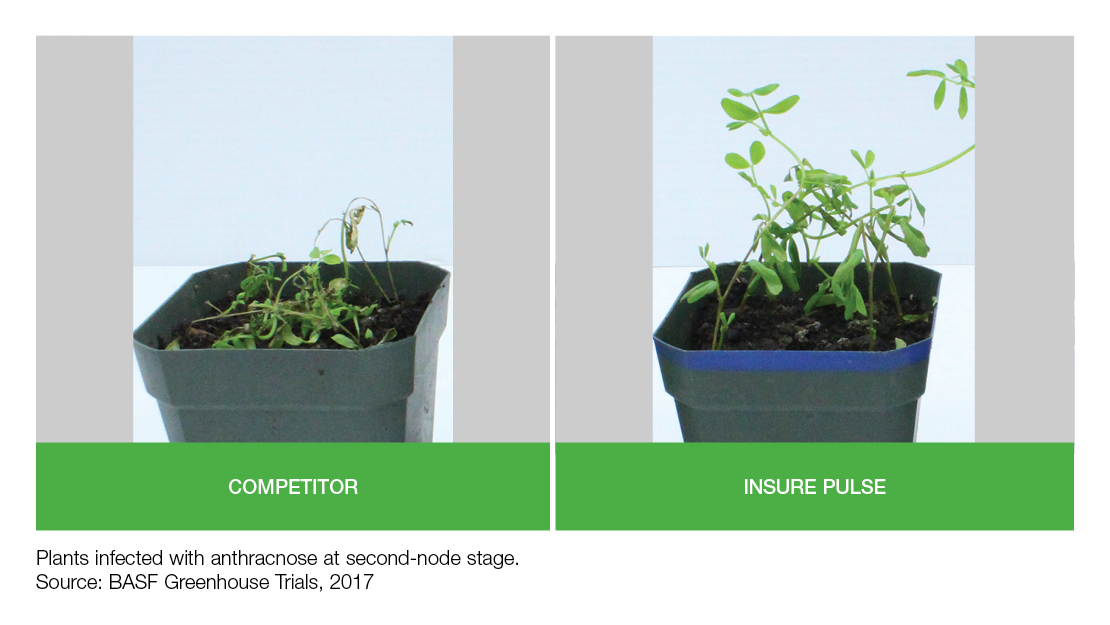

Increased seedling vigour with Insure Pulse vs competitor on lentils

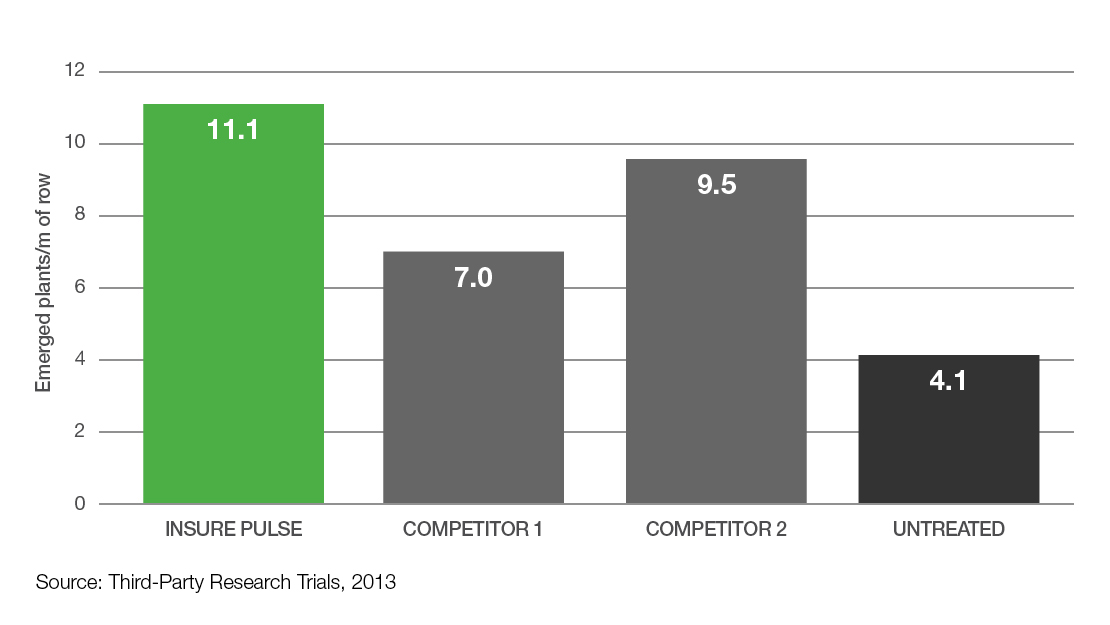

Lentils – More plants emerged under fusarium disease pressure

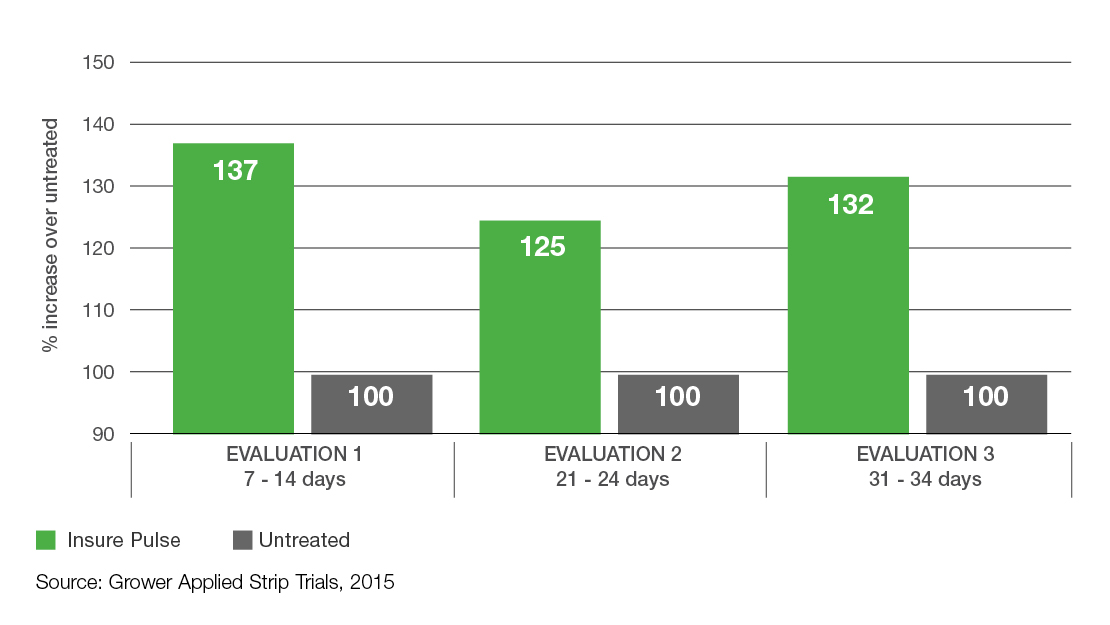

Flax – Increased emergence5

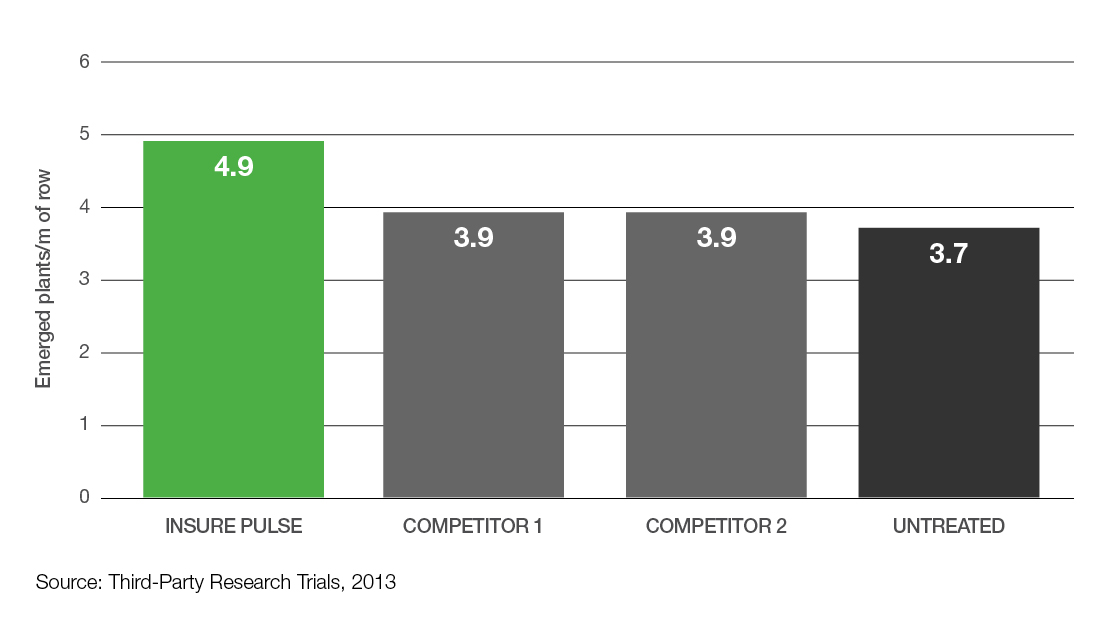

Field peas - Number of plants emerged under botrytis disease pressure

Product Info & Application Guide

Disease Management

Diseases controlled and suppressed

| Crops | Diseases |

|---|---|

| In pulses and soybean. |

|

| In flax and mustard. |

|

3 Suppression only.

4 In mustard only.

5 Each evaluation was completed on the same row at three different dates for each treatment.

Application Tips

Apply using standard slurry, gravity flow or mist-type seed treatment application equipment.

- Mix/agitate the product well before applying.

- Be cautious of weather and temperature of seed and seed treatment while treating. Keep seed treatment in a warm storage area and avoid treating seed that is colder than 0°C.

- Find the right flow rate to avoid plugging. Don’t start treating with the seed treater running at 100% capacity.

- If seed is dry, it can cause issues such as cracked hulls building up and plugging the metering roller/auger.

- Do not leave your seed treater alone when it’s running, as many things can quickly affect seed treating quality.

- Be attentive to factors that can cause changes to nozzle pressure, including the power source to the pump, an object blocking the filter or the hose not reaching deep enough into the product.

- Be cautious of drying times and factors that can lengthen them, such as weather (air temperature, wind speed, relative humidity), seed temperature, seed moisture levels, seed type and water being added during treating.

- Dilution with water is not required unless recommended by the manufacturer of the seed treatment application equipment. If desired, increase the use rate proportionally to the dilution rate:

Ex: 100 ml water + 300 ml Insure Pulse = 400 ml/100 kg seed - BASF supports the addition of water to Insure Pulse to a maximum volume of 600 ml (300 ml additional water per 100 kg).

- Do not use treated seed for food, feed or oil production.

- In adherence with the “Seeds Act”, Insure Pulse contains sufficient pigment to

conspicuously colour and coat treated seed.

How Much to Apply

The application rate for Insure Pulse seed treatment is 300 ml per 100 kg of seed for pulses and soybeans, 300 to 600 ml per 100 kg of seed for flax6 and 600 ml per 100 kg of seed for mustard.

Crop |

Bushels (bu) treated per jug |

Bushels (bu) treated per 120 L drum |

Bushels (bu) treated per 450 L tote |

|---|---|---|---|

| Pulses7 | 120 | 1469 | 5510 |

| Soybeans | 120 | 1469 | 5510 |

| Flax6 | 64 to 128 | 784 to 1567 | 2939 to 5878 |

| Mustard | 72 | 882 | 3306 |

6 For flax (Linum usitatissimum), use a higher rate of 600 ml/100 kg seed if: a) there is a history of high disease pressures in the field or b) where field conditions favour seed- and soil-borne pathogens. If using the 600 ml/100 kg rate, it is highly recommended that the seed be treated into a bin or truck box to allow the treated seed to dry prior to placing into the seeder hopper. This will prevent clumping and bridging in the seeder.

7 Includes field peas, lentils (all classes), chickpeas, dry beans and faba beans.

FAQ

The colour from an Insure seed treatment has stained my equipment. What can I use to remove the stains?

BASF strictly adheres to regulations pertaining to the colouration of treated seed, enforced under the “Seeds Act”. Therefore, Insure Seed Treatments contain sufficient pigment to visibly colour and coat the seed. This can stain truck boxes blue or red. MS Schippers Foam or Enviro Clean can be used to help remove stains from the surface of equipment dyed by Insure seed treatments.

Can I dilute Insure brand seed treatments with water?

If desired, based on treating conditions, applicators can dilute Insure brand seed treatments with water. Increase the use rate proportionally to the dilution rate (E.g. 100 ml water + 300 ml Insure® Cereal FX4 = 400 ml/100 kg seed). BASF supports the addition of water to Insure Cereal FX4 to a maximum volume of 600 ml (300 ml additional water per 100 kg).

How long does seed treated with an Insure seed treatment stay good? How far in advance can I treat seed with an Insure seed treatment?

Seed treated with Insure seed treatments can be stored for up to one year without impacting seed germination and viability. Beyond one year, seed should be re-treated to maintain product efficacy

Where can I find information on properly calibrating my seed treating equipment with Insure brand seed treatments?

Calibration documents for A4, G3 and G40 treating systems can all be found on the website product pages for each Insure brand seed treatment.

Where can I find information on application rate by crop for Insure brand seed treatments?

Treatment rate is based on total weight, not the number of bushels of seed or bushel weight. Each Insure brand technology sheet provides details on application rates for all labeled crops by pack size.